This article will discuss various methods for AC Motor Rewinding, including the Phase-band division method, Distributed winding, and Sandblasting. It will also discuss the cost associated with these methods. Here are some common mistakes to avoid. Make sure you carefully read this article before beginning the process. After completing the process, the finished motor will be ready for use again. Here are some tips to help you get started.

Page Content

Phase-band Division Method

Using the phase-band division method to rewind an AC motor allows the speed range to be expanded. However, it requires access to both the ends and center tap. In addition, the method only works for ratios 3:1 or lower. This paper describes a simple switching method for AC machines. Its advantages are:

The Phase-band division method involves rewinding the rotor and stator in order to obtain a continuous rating that is equal to the continuous rating of the AC motor. This method is more costly than the other methods. It is effective in dynamic braking but is not as reliable as the others. The rewinding process has three main phases: reversal, plugging, and polarization.

Distributed Winding

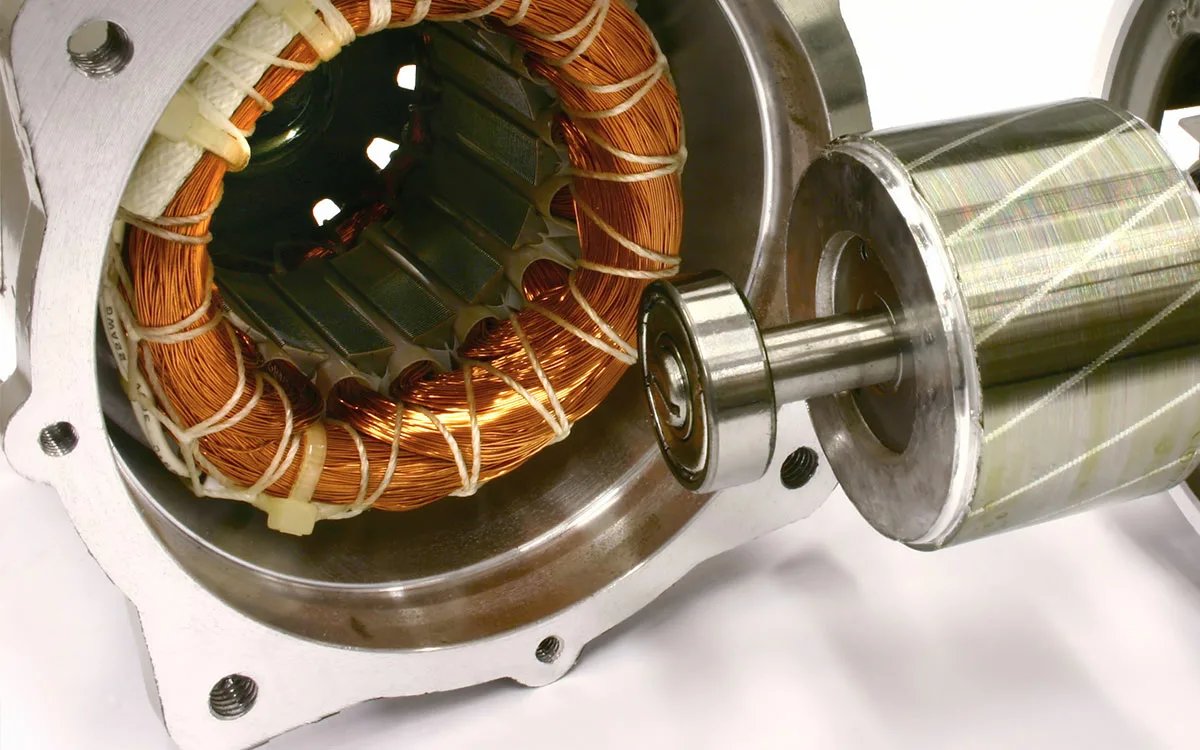

Induction and synchronous machines use a type of distributed winding in the armature of their motors. Distributed windings are made up of several strands of wire connected in parallel and wound into a coil with a certain number of turns. This type of winding has many advantages. It improves the shape of the induced EMF, provides efficient cooling, and improves dynamic balance. In addition, it has a lower inductive reactance and a higher armature reaction.

The output voltage of a motor using this type of winding is the highest, and it is also the most efficient. The difference between a concentrated winding and a distributed one lies in the level of automation. Distributed windings can be used in many different applications, from AC motors to synchronous machines.

Sandblasting

Before undergoing AC Motor Rewinding, you should consider the benefits of steam cleaning and sand blasting. Steam cleaning provides a quick clean but requires a lot of drying time. Some cases, drying takes up to a day. Additionally, sandblasting creates a cloud of dust that could trap grit and short out the core. Also, if your company is located next to a commercial establishment, your neighbors might complain to the EPA.

The process of sandblasting requires a novel nozzle. This nozzle has a beveled end to fit into the slot and a metal coupling to attach the sand blasting source. The nozzle is inserted into the stator slot and emits an abrasive. The abrasive will remove the material while preventing damage to the exterior of the slot. The process also allows for the easy replacement of ceramic members that have broken.

Cost

When you have an old AC motor that is showing signs of wear and tear, it may be time to consider AC motor rewinding as an option. While you can purchase a new motor, rewinding can often be a much more cost-effective option. Additionally, new motors can often save you money while reducing environmental impact. You can decide which option is right for your needs by comparing bids from different companies and weighing the pros and cons of each.

Rewinding is also often environmentally friendly, as compared to manufacturing a brand-new motor from scratch, which has a higher environmental impact and carbon footprint. Visit Ghaima Group to know more.

An experienced businessman. Traveler and philanthropist. A blogger with experience of interaction.